- Knowledge sharing of several major application instruments of pressure transmitters in sulfuric acid production

In the long-term practice of sulfuric acid production, the application of pressure transmitters has occupied an important position in the field of sulfuric acid instruments. They can not only accurately measure pressure but also effectively monitor liquid level and density. To ensure long-term stable operation and accuracy when measuring different parameters, it is necessary to fully consider the influence of special media in different usage environments on factors such as temperature and corrosiveness that the pressure transmitter can withstand. Therefore, meticulous consideration is needed during the design and installation process. Next, a detailed design analysis will be conducted starting from multiple different application scenarios.

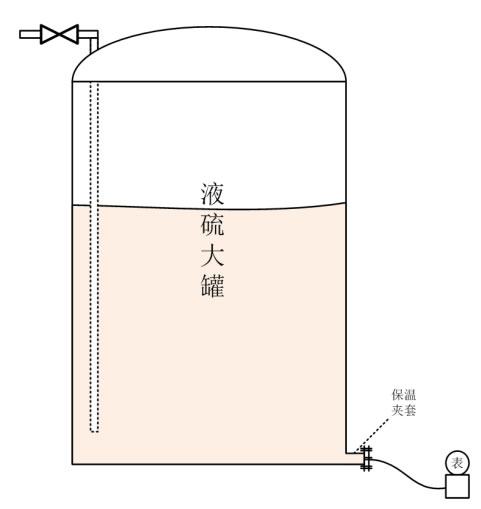

Liquid level measurement of large liquid sulfur tanks

To prevent the large liquid sulfur tank from being full or empty due to the distortion of a single liquid level measurement, two liquid level gauges with different measurement principles need to be adopted. Radar level gauges and magnetic flap level gauges are usually selected. However, due to the height of the large liquid sulfur tank exceeding 10 meters, the magnetic flap level gauge is difficult to install and prone to damage, and its later maintenance is inconvenient. Therefore, the pressure transmitter with a low failure rate and easy maintenance has become the ideal choice for measuring the liquid level of the large liquid sulfur tank. When installing the pressure transmitter, be sure to position the pressure sensor horizontally below the detection diaphragm. It is particularly important to note that liquid sulfur is prone to solidification, which not only affects the measurement but may also damage the diaphragm of the pressure transmitter. Therefore, insulation jackets need to be installed at the connection points of the lead-out pipe and the flange. The top air section maintains a constant pressure with the atmosphere. By measuring the pressure at the bottom of the large liquid sulfur tank and combining it with the known density of liquid sulfur, the liquid level can be calculated through a formula. In addition, the pressure when the large liquid sulfur tank is fully filled needs to be calculated to select a pressure transmitter with an appropriate range.

微信截圖_20251014152232_20251014.png)

For example, the height of the large liquid sulfur tank is 10 meters, and the calculation formula for the pressure transmitter range is: P = 10 × 1.8 × 9.8 = 176.4 KPa. The density of liquid sulfur is set at 1.8 g/cm³.

Measurement of liquid level in the refined sulfur tank

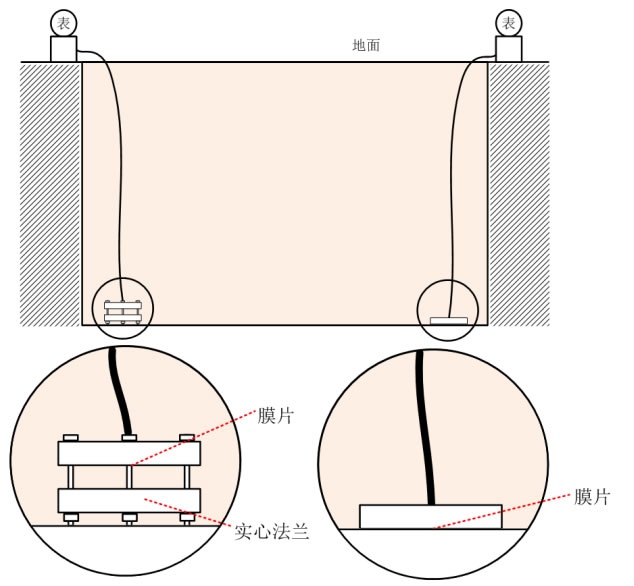

As the refined sulfur tank is located underground, the above installation method is no longer applicable. Instead, the measuring equipment can be directly placed at the bottom of the refined sulfur tank. However, this measurement method also brings new problems: due to the presence of H2S gas in the refined sulfur tank, it will accelerate the corrosion of the capillary tube. Long-term use of this method will also reduce the service life of the pressure transmitter.

To address the above issues, during the selection stage, it is advisable to consider using silicone resin as the capillary filling liquid and adopt capillary tubes made of PVC material. The reason for doing this is that PVC material is resistant to H2S corrosion and its heat transfer efficiency is relatively low, thereby greatly reducing the corrosive impact of H2S gas on the service life of the pressure transmitter. It is worth noting that before placing the equipment in the refined sulfur tank, the initial zero point of the meter head should be set to positive pressure, equivalent to the pressure at the height of the refined sulfur tank, to counteract the negative pressure generated after being placed at the bottom of the tank.

During the measurement process, it is necessary to ensure that the diaphragm is located at the bottom of the tank as much as possible. However, if there are a small amount of impurities deposited at the bottom of the groove, these impurities will directly come into contact with the flange and diaphragm, affecting the measurement results and may even cause the diaphragm to be scratched. To avoid this problem, it is recommended to install a flange on the diaphragm flange as a base. In this way, even if there are a small amount of impurities, they can effectively isolate their interference with the measurement, prevent the diaphragm from being damaged by friction due to direct contact with the bottom of the tank, and thus play a protective role for the diaphragm.

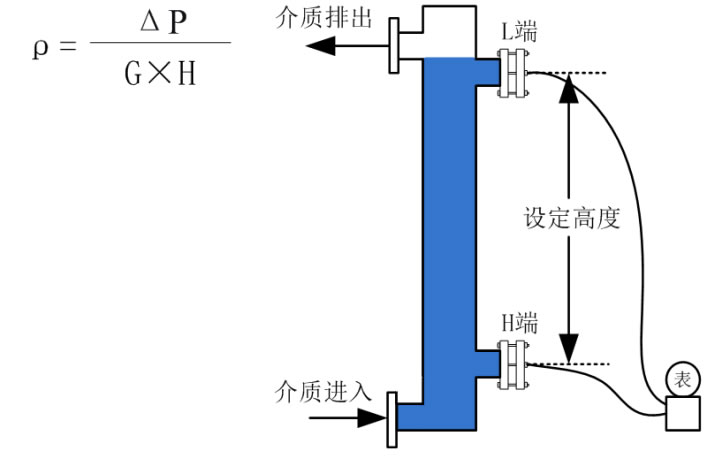

The pressure transmitter measures density

Pressure transmitters are not only suitable for measuring liquid level and pressure parameters, but also for determining the density of media. Based on the pressure formula, the density of the medium inside a container with a known set height can be accurately measured. Based on this principle, the corresponding structure can be designed.

Set the distance between the two diaphragms of the pressure transmitter to be fixed, and install the pressure transmitter sensor below the horizontal position at the H end. After the instrument is zeroed, the medium is filled in to completely submerging the L-end diaphragm. The pressure value is measured, and then the density of the medium can be calculated.

Measurement of boiler drum liquid level

The previously shared methods for measuring liquid level with pressure transmitters are all applicable when there is no pressure on the gas phase side. However, when the steam drum is in a high-temperature and high-pressure state of 3.8MPa or 6.4MPa, the conventional measurement methods are no longer applicable. When using a pressure transmitter to measure the liquid level in a steam drum, it is necessary to measure the pressure difference between the gas and liquid phases. Due to the excessively high temperature, to prevent direct contact between the instrument and the steam drum, a double-chamber balancing container should be connected between the instrument and the steam drum to achieve accurate measurement of the steam drum liquid level.

Before the steam drum is put into use, the double-chamber balance container should be filled with water by opening the plug. When put into use, open the two valves connected to the steam drum again. The measured liquid level range h is the distance between the liquid-phase side connection pipe and the gas-phase side connection pipe.

During the measurement process, the outer chamber of the double-chamber balance container and the liquid level of the steam drum apply the principle of a communicating vessel to ensure the same liquid level. Water vapor enters the outer chamber of the double-chamber balance container through the connecting pipe and condenses into condensate water, always keeping the liquid level in the inner chamber at a high level. Subtract the pressure at the H end from that at the L end to obtain a Δ P. Calculate H according to the following formula, and get the drum liquid level at this time from h+H.

微信截圖_20251014152435_20251014.png)

(Edited by Jiang Xingwang, Reviewed by Yang Haidong)